The main purpose of the carburizer is to better increase the carbon element lost in the steelmaking process. If the carbon content in the steelmaking process fails to meet the expected standard, a certain ratio of carburant should be put in. The purpose is to better increase the content of carbon in molten steel, and then smelt ideal steel. Carburizers are widely used and can also be used in the foundry industry. In forging, carburizers can reduce costs. Using carburizers as forging materials can greatly reduce costs, and carburizers are used for lubrication, which can effectively improve the quality of castings. Extend the service life and improve the quality gradually.

If you want to supplement the carbon content in the molten steel, you need to do a strict quality inspection on the added carburizer, so as not to bring too much sundries into the carburant, which will affect the quality of the steel. We all know that the carburizer is added in the later stage of steel smelting, so the determination of the content of impurities in the carburizer cannot be ignored.

Products Describe

The role of carburizer

Cast iron and cast steel castings will have a requirement for carbon, so the carburizer, as the name implies, is to increase the carbon content in molten iron. For example, the commonly used furnace materials in smelting are pig iron, scrap steel, and recycled materials. The carbon content of pig iron is high, but the purchase price is higher than that of scrap steel. Therefore, increasing the amount of scrap steel, reducing the amount of pig iron, and adding carburizers can reduce the cost of castings to a certain extent.

The use of carburizers can not only make up for the burning loss of carbon in the process of iron and steel smelting and ensure the carbon content requirements of specific grades of steel, but also be used for post-furnace adjustments. As an important raw material for melting molten iron in an induction furnace, the quality and usage of recarburizer directly affect the state of molten iron.

Adding a specific brand of recarburizer to the ladle after slag removal and degassing treatment can adjust the carbon content in the ladle to achieve the purpose of multiple numbers in one ladle. The materials used in the recarburizer mainly include graphite, graphite-like materials, electrode blocks, coke, silicon carbide, and other materials. Commonly used electrode blocks and silicon carbide recarburizers have the advantages of high carbon content and strong oxidation resistance, but the production process is relatively complicated and the cost is high. Coke powder and graphite are used as recarburizers, and the production cost is lower than that of electrode blocks and other materials, but the content of ash and sulfur is high, the content of carbon is low, and the carburizing effect is not good.

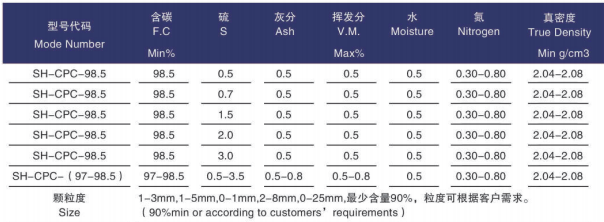

Product Parameters

Packing and Shipping

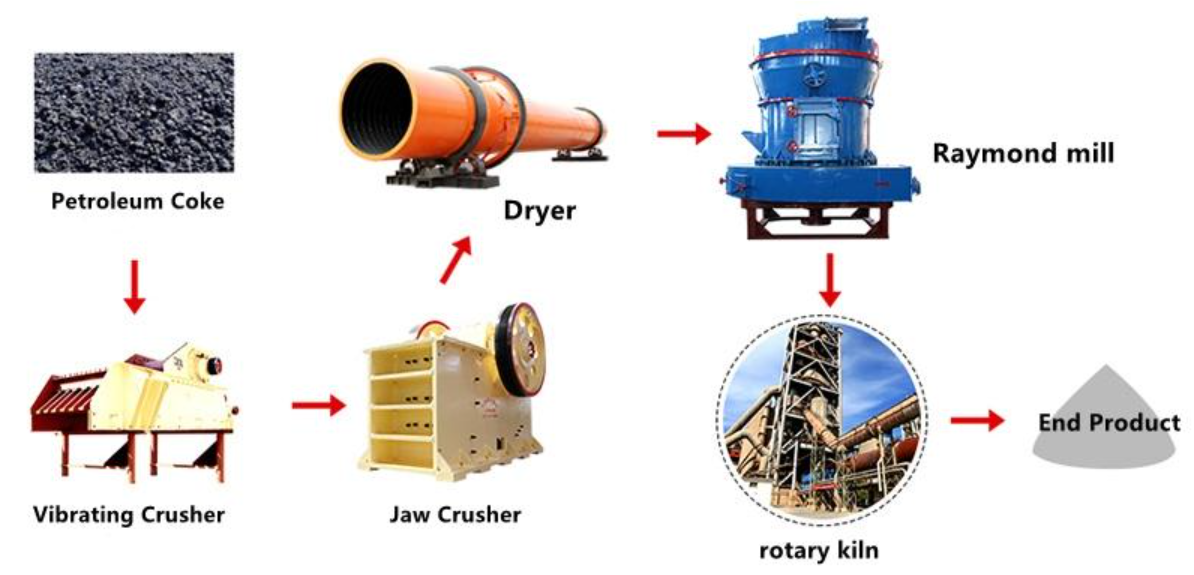

Manufacture Process

FAQ

1. What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A: We consider honest as the life of our company, your order and money will be well guaranteed.

3. Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4. Where are you? Can I visit you?

A: Sure, welcome to you visit our factory at any time.

5. How about the delivery time?

A: Within 15-30 days after we confirm you requirement.

6. What kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash are all accepted if you have other payment, please contact me.

Inquire Basket (0)